|

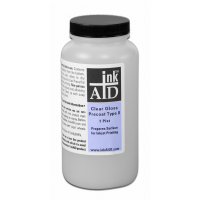

inkAID Clear Gloss Type II Inkjet receptive coating can be applied to any material that cango through your printer. It provides a clear gloss finish that allows the underlying surface toappear through the coating. Clear Gloss Type II Coating Provides excellent print quality. Produces clear, vibrant colours with deep blacks. Has very good adhesion to metals that are properly prepared to accept water based coatings. Will not add a significant amount of thickness to your media. Substrates coated with inkAIDClear Gloss Type II coating will go through your printer just like any other material. Is water based and very safe to use. It's in the same category as water based artist mediumsand grounds. As with any coating, remember to use with adequate ventilation. Using inkAID Clear Gloss Type II Coating Always stir the coating gently, but thoroughly, from the bottom using a clean spatula orspoon before use. inkAID Clear Gloss Type II coating cleans up with water, even after drying. Wearappropriate clothing and work in area suitable for painting. Never work directly from the container. Always pour a working amount of inkAID ClearGloss Type II coating into another clean container. Never pour unused coating back into thecontainer. Make sure all of your tools and brushes are clean and dry before beginning work. Store inkAID Clear Gloss coating in a cool, dry environment. Never allow the coating tofreeze. The final appearance of your print will depend on how much coating is on the surface of thesubstrate. Be sure to thoroughly coat the entire surface of the substrate. It is the inkjet receptive coating that absorbs most of the ink and properly positions the inkdroplets to create the print. Porous substrates like paper, fabric, and canvas will absorb some of the coating into thematerial but enough is left on the surface to provide excellent printability. Usually, lesscoating can be used on porous substrates as it will absorb a significant amount of the inkvehicle. When getting started with a new substrate test a few small pieces. Non-poroussubstrates like metal, plastic, and film will have all of the coating on the surface. With thesesubstrates the coating must absorb all of the ink so a heavier coating layer is needed. Makesure your substrate is on a smooth level surface. All metals must be cleaned thoroughly to remove processing oils before coating withinkAID Clear Gloss Type II coating. Always check your printer specifications to determine maximum media thickness for yourprinter. inkAID coatings will impart a slightly stiffer hand to lighter weight papers and fabrics. Applying inkAID Clear Gloss Type II Coating Always work with clean tools and brushes. inkAID Clear Gloss Type II coating can be applied with a foam brush, good quality bristlebrush, coating rod, or a Paasche VLS Airbrush sprayer. It can also be used on paper and other porous materials. |

back

top